In an industry where precision is everything, speed, trust, and human connection can be the deciding factors between progress and paralysis

A Family Business Rooted in innovation

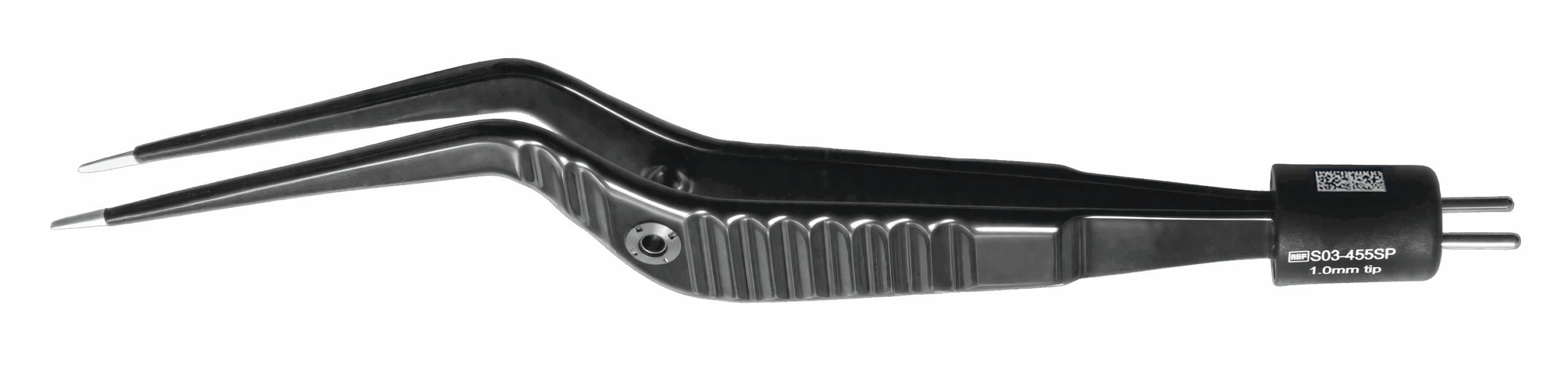

For Brian McBrinn, president of Stingray Surgical Products, precision manufacturing isn’t just a career, it’s a family legacy. Founded by his father, the company began with gynecological instruments and evolved into a leader in electrosurgical device manufacturing, including bipolar forceps, electrified tweezers that cut and coagulate tissue during surgery.

“I grew up in this business,” Brian said. “I started working here in high school, and over time, we’ve moved from a lot of hand machining to automating our processes.”

Stingray’s deep roots in craftsmanship and its commitment to continuous improvement are clear. Based in Boca Raton, Florida, the company has built a reputation for high-precision machining of tiny titanium, stainless steel, and advanced plastic components. Parts so delicate they often require finishing under a microscope.

Agility as a Competitive Advantage

When asked what makes Stingray successful in such a specialized market, Brian’s answer was simple: AGILITY

“Because we’re not a huge multi-national we can move fast,” he said. “When you call here, you talk to someone who knows what they’re talking about. With our larger competitors, you end up playing phone tag just to get an answer.” That ability to respond quickly, without corporate red tape or layers of approval, has helped Stingray thrive in an industry dominated by conglomerates. “When companies get big, every decision takes forever,” Brian explained.

“For us, we can pivot immediately to meet a customer’s need. That’s where we win.”

It’s a philosophy that mirrors Eureka’s own culture, a company built on responsiveness, technical depth, and customer connection rather than bureaucratic processes.

As Shaun Mymudes, Eureka’s Business Development Manager, noted during the interview:

“We’ll never act like a big company, no matter how big we get. The best companies to work with are the ones that stay agile.”

From Handwritten Code to Digital Confidence

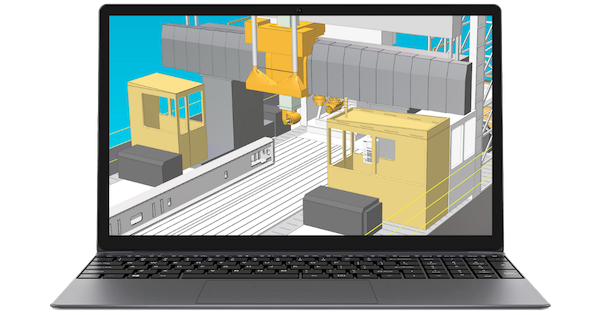

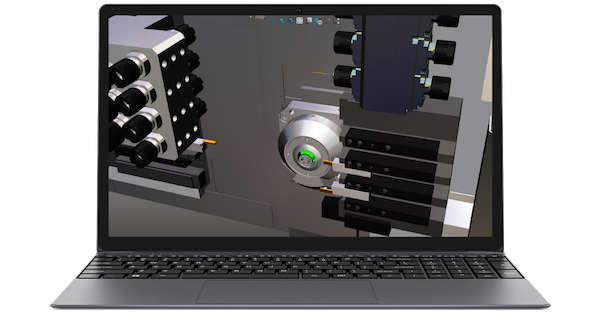

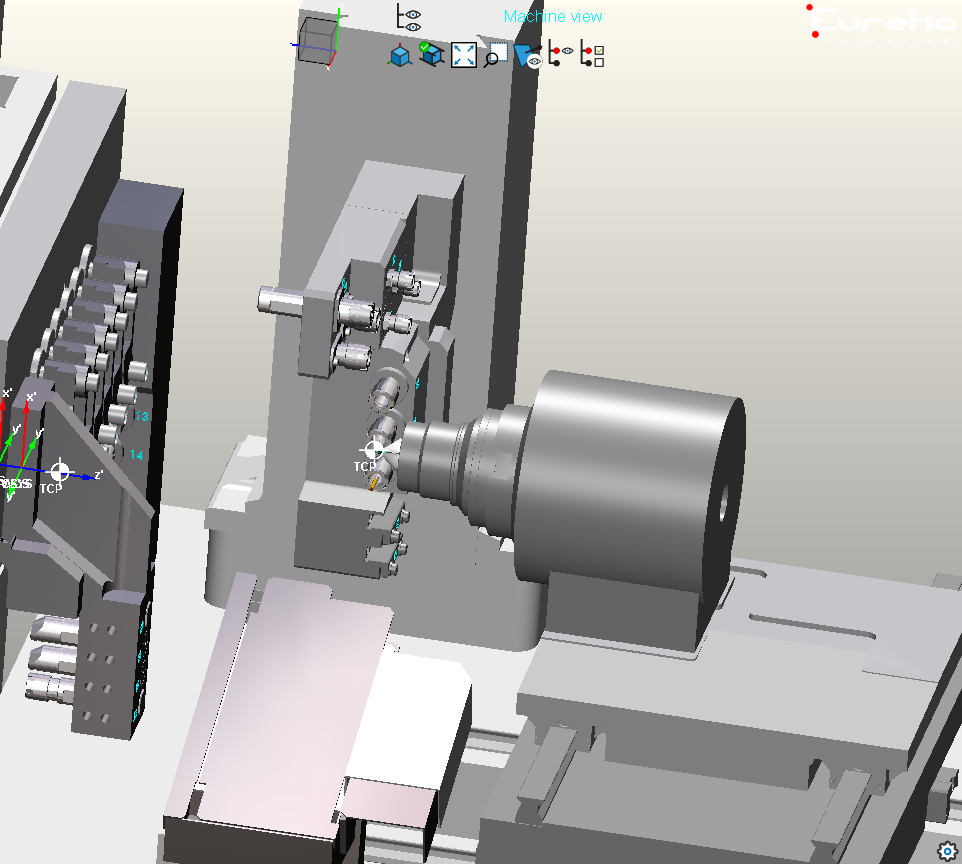

For years, Stingray relied on handwritten G-code for their complex CNC Swiss machines, an approach that required skill, patience, and nerve. But as the company expanded into 8-axis Swiss machining for high-value parts, the stakes grew higher.

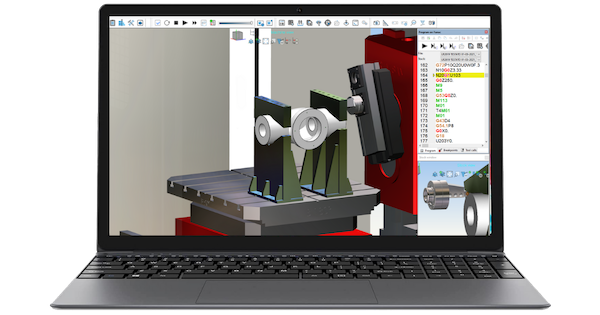

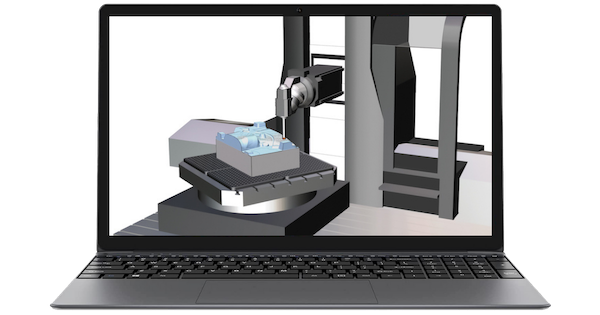

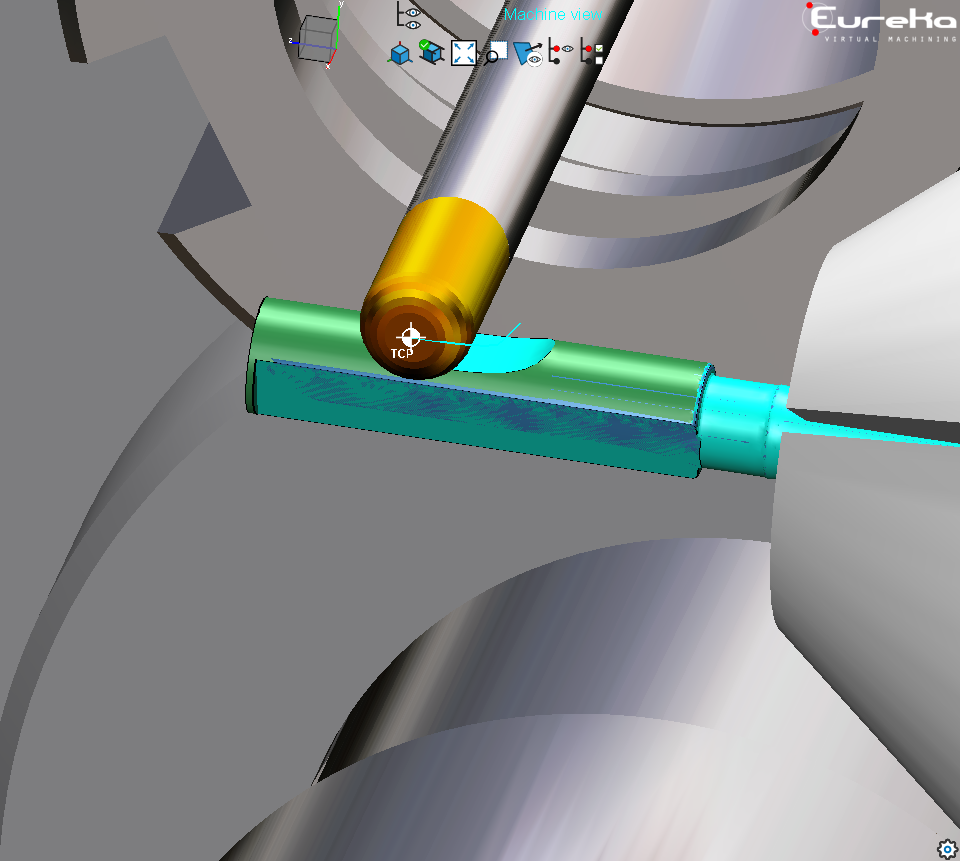

“We were flying blind,” Brian said. “With the kind of parts we make, micro components where you can barely see what’s going on, one wrong line of code could be costly.” That’s when he discovered NC Coder, Eureka’s Programming and Simulation for Fusion 360. Before Eureka, Brian would generate code fragments in Fusion or HSMWorks, then manually piece them together. With Eureka NC Coder he could bring in multiple tool paths, assign them to channels, and then Simulate, he could program, visualize, and verify every toolpath before ever touching a machine.

“It’s perfectly accurate,” he said. “What I see in Eureka Simulation is exactly what happens on the machine.”

The impact was immediate:

• Fewer revisions: from 10 down to just 1 or 2 before production.

• Higher confidence: “I don’t have to go back and forth to the machine anymore.”

• More accuracy: Eureka even revealed that one of Stingray’s machine axes was off by a full

millimeter: an issue missed by the factory itself.

• Safer operations: “If you have a $200,000 machine and don’t want to crash it,” Brian said, “Eureka is

worth every penny.”

Empowering the Next Generation of Machinists

As a leader who grew up on the shop floor, Brian sees technology as a way to bridge generations in manufacturing. “A lot of our employees are younger and already know Fusion,”he said. “Eureka made it easy for them to move into CNC programming without learning a whole new CAM system.”

The software not only increased productivity – it helped Stingray build a stronger, more confident team. “Training was simple,” Brian explained. “Two to three hours and you’re checking programs like a pro. It’s given our people the ability to verify and trust their work.”

The Power of Small: When Agility Meets Support

In the end, what truly unites Stingray Surgical and Eureka is their shared belief in responsiveness. Both

companies are proof that small doesn’t mean limited, it means capable, connected, and fast.

“Every time I’ve called support, Eureka has been right there,” Brian said. “They’re always ready to jump on a Teams call and fix the issue.” That responsiveness builds trust, the kind of trust that drives innovation forward without hesitation.

“Stingray embodies everything great about small companies,” said Shaun. “They’re creative, agile, and caredeeply about quality. That’s exactly who we want to work with, and exactly who we are.”

Conclusion

In an industry where precision is everything, speed, trust, and human connection can be the deciding factors between progress and paralysis. For Stingray Surgical, partnering with Eureka wasn’t just about simulation software – it was about confidence, collaboration, and control. When two nimble companies join forces, innovation doesn’t just happen faster, it happens smarter. Eureka Simulation + Stingray Surgical: Small company agility. Big results.