Aspectus, LLC – is a leading US based manufacturing consulting firm founded by Glenn Junkins. They provide advanced CNC programming & manufacturing services to a diverse group of clients in several key industries which include: Aerospace, Automotive, Defense, Medical and Industrial.

Their manufacturing services include CNC programming from 2.5 thru full 5 axis and multi-axis turning with live tooling. In addition, they provide full 3D modeling and fixture design services. They utilize CamWorks and SolidWorks for their CAD/CAM software.

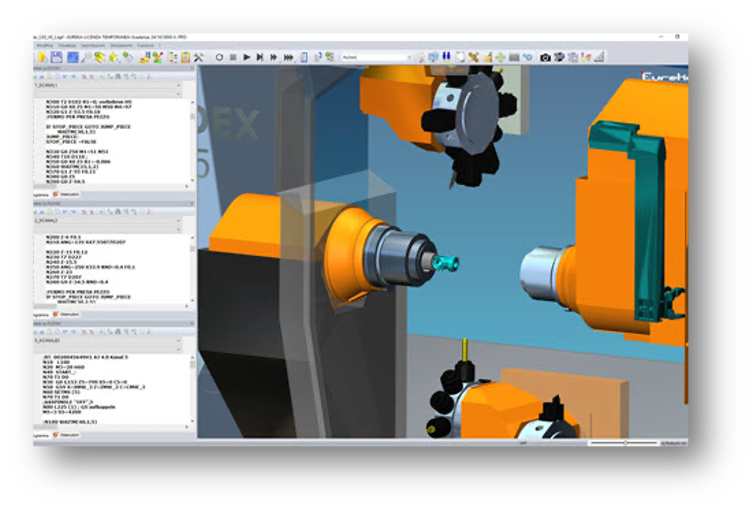

Aspectus, LLC began looking at G-code

simulation software in 2018. They wanted robust full 3D verification of G code programs and detection of any possible program errors prior to their customers running on their CNC machines. After extensive research and evaluation of several software products, they selected Eureka G-code by Roboris, Srl

We asked Glenn Junkins – Owner what were the key differentiators as to why he choose Eureka: “Out of all of the Machine Simulation Software I evaluated, Eureka interfaced the best with Camworks.” He added: “Cost was another factor in my selection. Eureka was my 1st choice after working with other machine simulation resellers. I found Eureka to have the best value for the price”.

Glenn said his company has benefitted greatly from Eureka G-code: “The more I use Eureka the more I love it. It’s capable of picking up not only tool path errors, but also syntax errors, and over travels in the program. This has been an excellent benefit when creating programs on complex machines that require translation of work coordinates and or parametric programming”.

Glenn said his company has benefitted greatly from Eureka G-code: “The more I use Eureka the more I love it. It’s capable of picking up not only tool path errors, but also syntax errors, and over travels in the program. This has been an excellent benefit when creating programs on complex machines that require translation of work coordinates and or parametric programming”.

He also mentioned: “Roboris has come through for me on all requests. One time in particular I had a special request for a machine that was a hybrid manual/CNC vertical turret lathe with a retrofit CNC control. I told the team at Eureka we were going to change this vertical turret lathe by unbolting the Z-axis and manually turning the Z-axis from vertical to 12.5 degrees. Roboris worked with me in creating the machine to my client’s specifications, so I could create a parametric program to run the vertical turret lathe in a custom way. Fabulous job Roboris!”

“The learning curve for the product is easier than other software products I have used. I have an employee that was using another machine simulation software before coming onto the Aspectus team. He was able to jump right in using Eureka with very little training and work with not only g-code verification but also with the tool optimization features.”

Learn more about Aspectus, LLC: aspectus3d.com