Thanks to the integration, all data can be transferred directly from the Coscom ECO system to Eureka Virtual Machining.

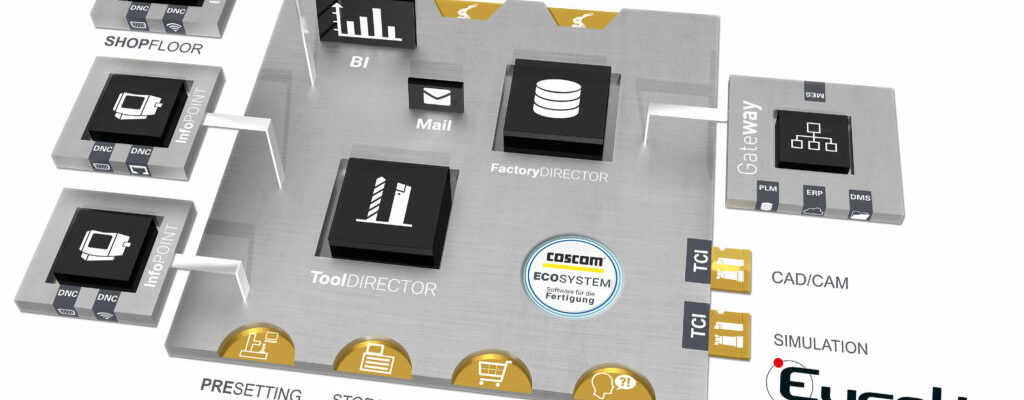

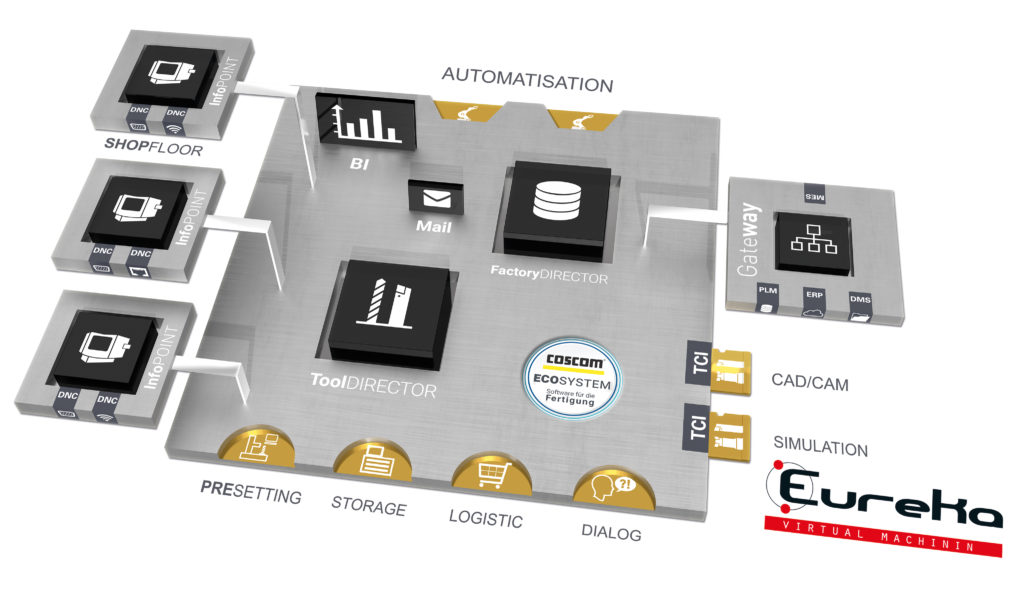

“The modern production landscape can only be maintained if the data relevant for the start-up of a machine tool is managed, organized and efficiently prepared," says Coscom. This includes the NC programs, tool information and instructions for the machining process. This is when Coscom’s central platform comes into play because it assembles all the information and networks the necessary IT infrastructure and, for example, the measurement and storage systems of the instruments. According to Coscom, this creates a seamless ECO system.

With the ECO system it’s also possible to “press" the start button of a CNC machine and see the simulation with a digital replica of the machine within Eureka.

The simulation of the machine in Eureka is then provided by the Coscom system, which is why you benefit from the complete performance of the whole process. The ECO system and the machine simulation can then communicate with each other. In other words, if the simulation of the Eureka machine is integrated into the Coscom ECO system, the data can flow directly between the two within the networked digital production.

“Thanks to Eureka we were able to integrate the virtual replica of the CNC machine directly into the platform. The simulation of the machine is delivered with all relevant data from the platform at the push of a button." Concluded Coscom

Complete sources