From their in-house CADCAM department, they can generate complete NC programs for multi axis CNC manufacturing using hyperMILL from OPEN MIND. Due to recent projects with the US defense sector, they were in need of full robot OLP simulation software that would fully simulate robot additive manufacturing applications using a digital twin of their robot cell.

From their in-house CADCAM department, they can generate complete NC programs for multi axis CNC manufacturing using hyperMILL from OPEN MIND. Due to recent projects with the US defense sector, they were in need of full robot OLP simulation software that would fully simulate robot additive manufacturing applications using a digital twin of their robot cell.

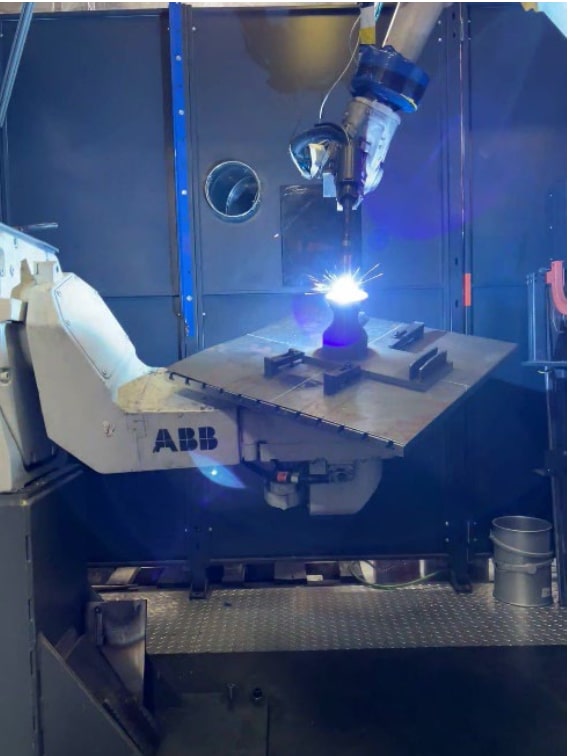

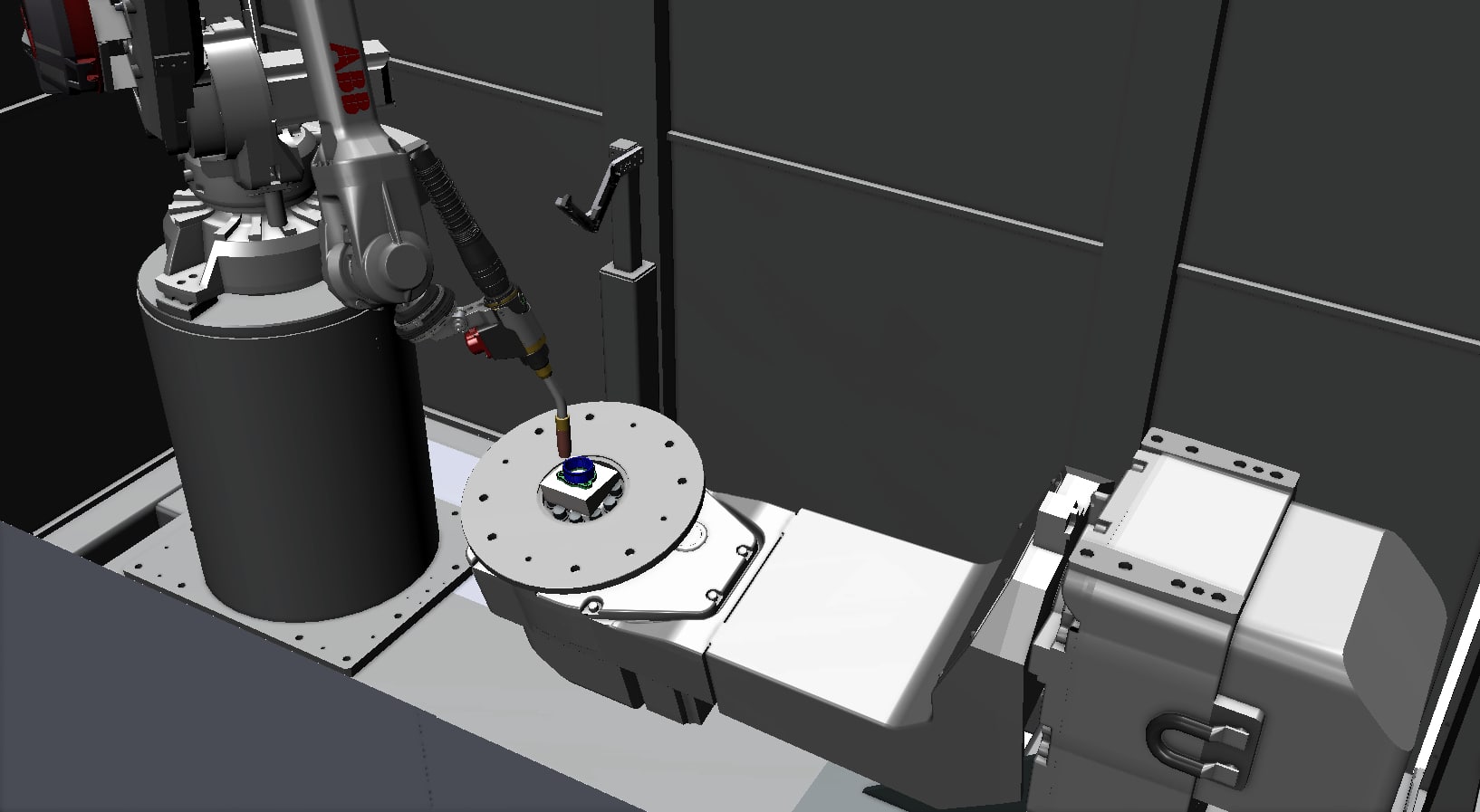

When researching various robot OLP software solutions, they found Eureka Robot. Eureka was able to create an exact digital twin replica of their in-house robot cell with an ABB robot.

Using the APT code from hyperMILL the Solvus team can check and fix any robot program errors in Eureka before running production. Eureka software detects a multitude of robot program errors such as: singularities, out of limits, spindle crashes and part gouges. Eureka supports all industrial robot brands including ABB, Comau, Fanuc, Kawasaki, Kuka, Staubli and Yaskawa.

Solvus has virtually eliminated robot program errors since implementing Eureka Robot OLP software.

Solvus team member and Senior Robotics Engineer Alex Michelson said: “Eureka has allowed Solvus to accelerate the implementation of advanced robotic motion for its additive manufacturing processes. Being able to resolve multi axis, coordinated motion through OLP simulation has enabled the Solvus team to significantly reduce deployment time and manufacturing risk. Additionally, having a true digital twin provided other optimizations in cycle times, minimized tool motion, and maximized working envelope.”

Solvus team member and Senior Robotics Engineer Alex Michelson said: “Eureka has allowed Solvus to accelerate the implementation of advanced robotic motion for its additive manufacturing processes. Being able to resolve multi axis, coordinated motion through OLP simulation has enabled the Solvus team to significantly reduce deployment time and manufacturing risk. Additionally, having a true digital twin provided other optimizations in cycle times, minimized tool motion, and maximized working envelope.”

Learn more about Solvus Global at: Solvus Global

Learn more about Eureka Robot software: Roboris Roboris USA, LLC

1846 E Innovation Park Dr Suite 100

Oro Valley, AZ 85755 800.339.5751 info@roboris.com