Eureka G-code

Eureka G-Code and Eureka Chronos for the mold sector

Reduce production costs and eliminate risk of collisions

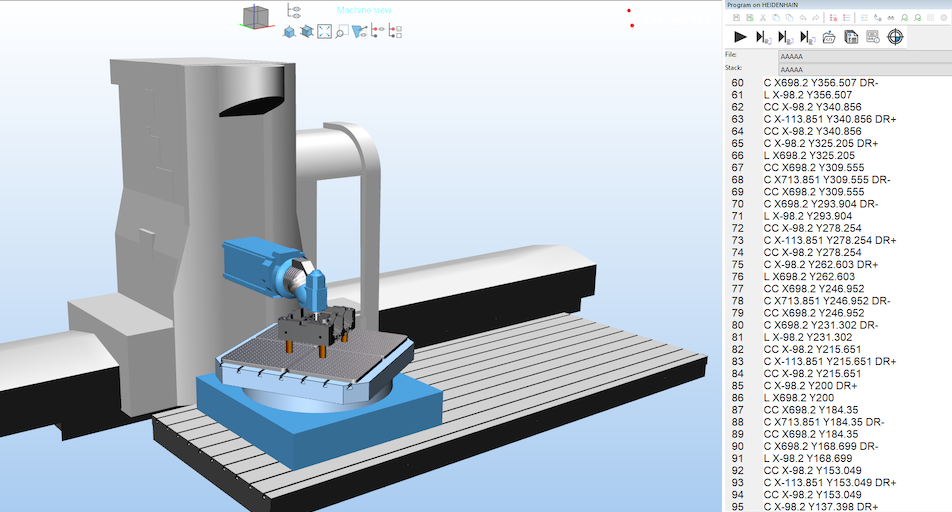

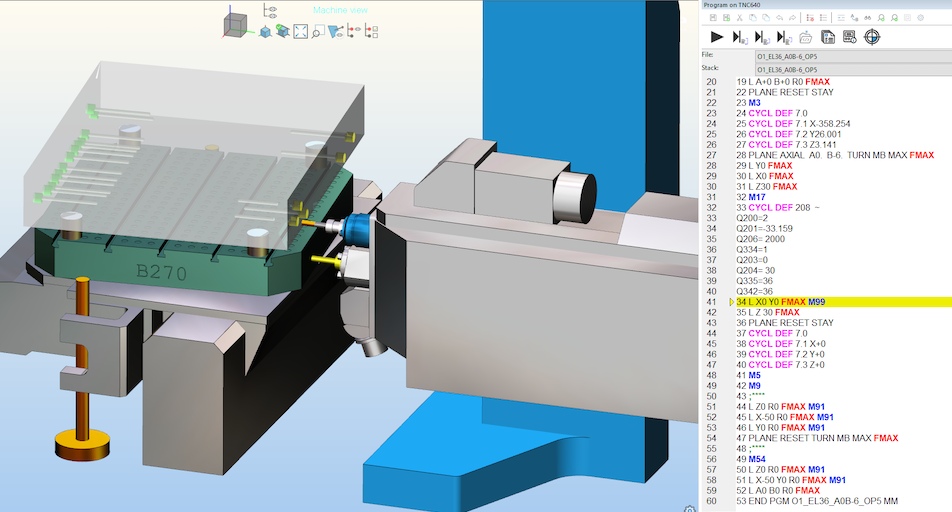

Independent simulation

With Eureka G-Code you get an independent G-code simulation that’s 100% reliable. You’ll avoid programming errors that cause collisions and costly production downtime and eliminate late deliveries.

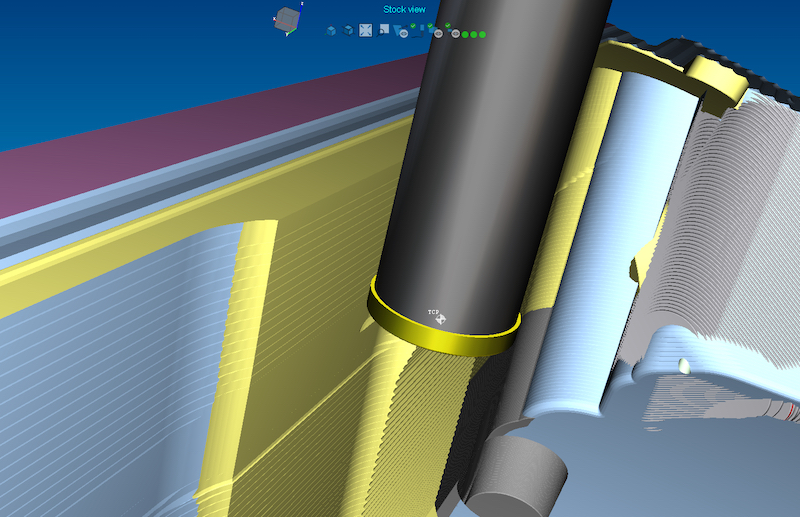

Reliable digital twin

Reliable digital twin for any type of kinematics and controller, including machines with more than 5 axes. You will have a complete collision check, including check between cutting edge and finished piece, and between tool holder and stock being machined, near-miss control between cutting edge and equipment, check for pre-holes for tapping and a verification of the limit switches.

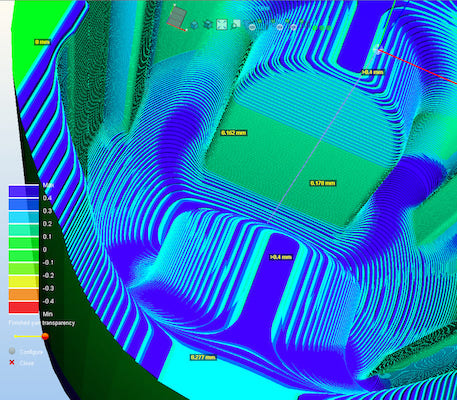

Super accurate comparison

With Eureka you can have highly accurate comparison between machined piece and 3D of the finished one. This tool allows you to compare the CAD model of the finished product directly with the model of the machined blank obtained in simulation to identify and measure any differences, identifying gouges, excesses of material or other inconsistencies.

With Eureka you can have highly accurate comparison between machined piece and 3D of the finished one. This tool allows you to compare the CAD model of the finished product directly with the model of the machined blank obtained in simulation to identify and measure any differences, identifying gouges, excesses of material or other inconsistencies.

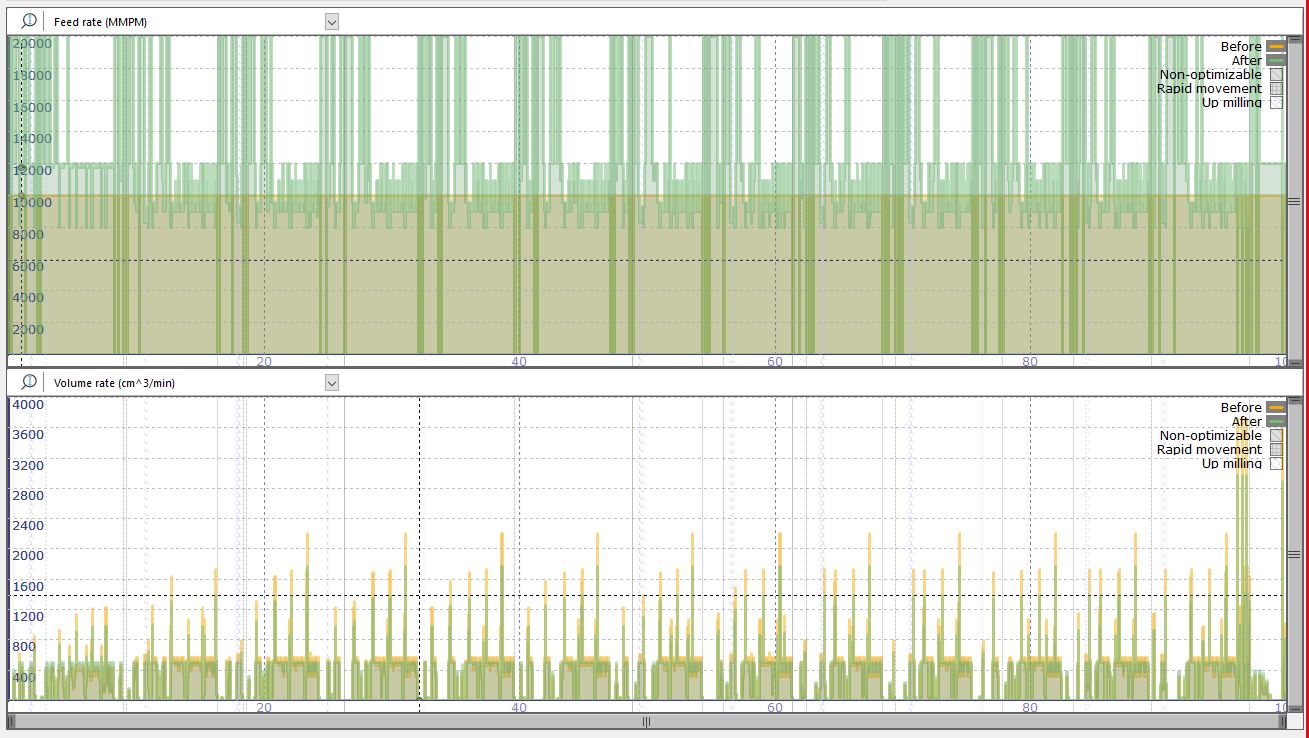

Cutting conditions check

For example, keep under control the volume removed in the unit of time for long tools that tend to vibrate. Ramp removal control for insert tools.

Eureka Chronos

The Eureka Chronos module optimizes the cutting conditions of the tools by modulating the feed rate. Thanks to an innovative method patented by Roboris, the optimization process is fully automated and the results are extraordinary.

On average, Eureka Chronos users see a reduction in machine time of more than 15%, 2 times greater tool life and a smoother machining with less chatter.

Eureka Chronos is available both integrated with Eureka G-Code for those interested in verifying and optimizing programs, and as standalone product for those needing optimization only.

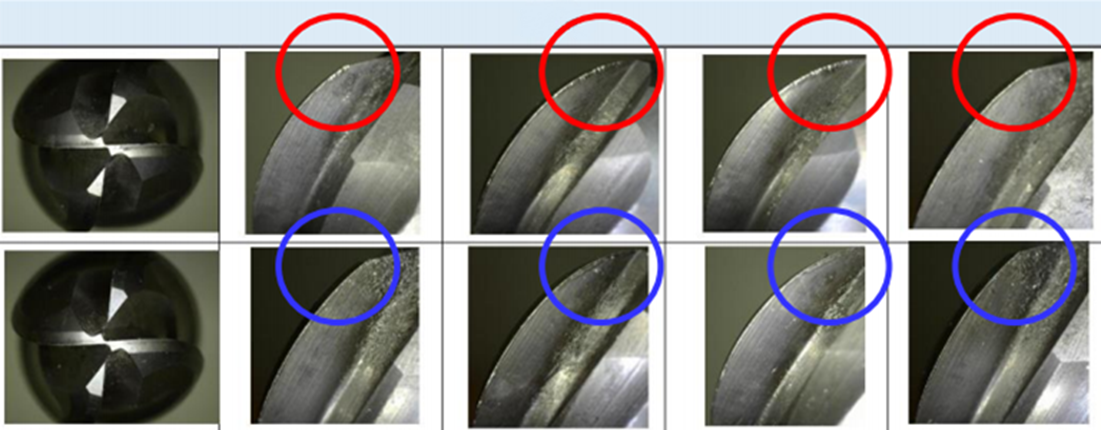

The case study

Sector: production of automotive molds

CNC: Mitsui vertex 75X II

Material: Daido DH31-S (HRC 48 ± 1)

Blank size: 308mm × 258mm × 95.5mm

Processing time | Without Eureka Chronos | With Eureka Chronos |

| |||

Roughing | 70 min | 55 min | -21% | |||

Semi finish | 29 min | 19 min | -35% | |||

Tool wear | With Eureka Chronos | ||

Roughing | Reduced | ||

Semi sinish | Equal |

Interfaceable

Thanks to the interfaces available for the major CAD / CAM systems and the main tool managers, it is possible to transfer blank, finished, equipment, programs and, above all, tools in a few clicks of the mouse.

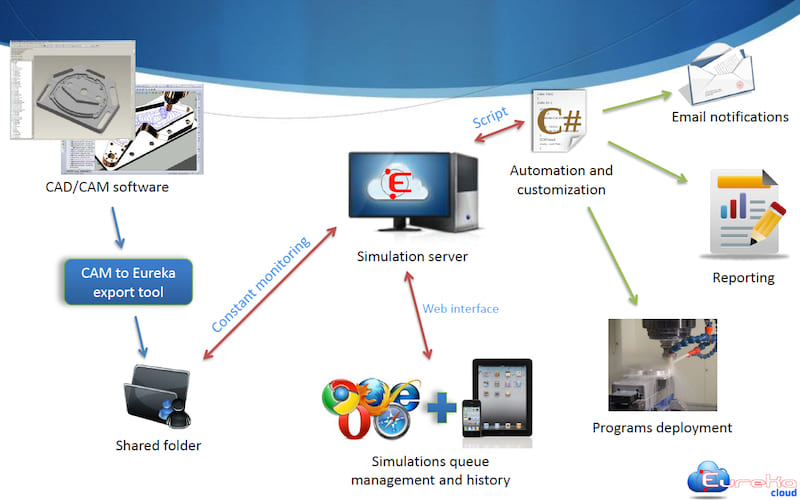

Automated

With Eureka Cloud it is also possible to implement an automatic simulation service in the company. CAM operators will only have to worry about generating the files with the interface and sending them to the service. Eureka Cloud will take care of distributing the simulations to be done on the networked PCs, scheduling them at the appropriate times, recording the entire history of the simulations in the company database and notifying the results when the simulations are completed.

Some customers