Eureka G-code

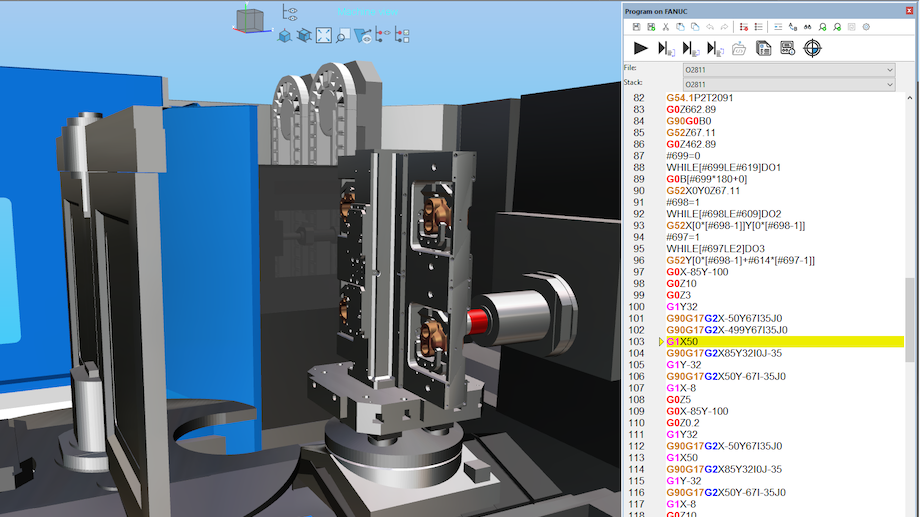

PRECISE AND RELIABLE DIGITAL REPLICA

Verify the parametric programming of your products with Eureka G-Code

Leader in ISO simulation for hydraulics and valve component production

Horizontal machining centers with multi-piece pallets or D'Andrea heads, the boring machines for large valves with head change and multi-axis are perfectly simulated in Eureka G-Code with a precise and reliable digital replica.

Advantages

> Parametric programs verification

>Creation of programs directly in Eureka G-Code, on computer

> Reset programming errors

> Reduction of machine preparation time. The tests and any corrections are made on the computer without engaging the machine

A complete and reliable simulation

– Simulation of programs created both manually and post-processed by a CAM

Complete digital model of the real machine with accurate emulation of the controller

Programs with parameters, variables, subroutines, manufacturer cycles such as:

Siemens G153-G500, SUPA, CYCLE 800, CYCLE976, CYCLE 81-87

Heidenhain PLANE SPATIAL, M91-M92

FANUC G68.2, G43.4, G81-G87, G53, G54.1P1

Multi-piece machining

Probing cycles

– Supports all types of tools, including:

Special tools with Multi-cutting edges

Bareni in Tirata

Angular heads

D'Andrea heads

Tappers

– Seamless Interfaces with CAD / CAM systems and tool managers

Interfaces for the most common CAD / CAM systems and tool managers

Ability to import existing digitized tool libraries

– Estimation of the useful cycle time to improve production times

– Super accurate comparison

Some customers

Old parametric programs can be modified and checked in Eureka G-Codea