Eureka G-code

Simulation for CNC Machine Tools with Eureka G-Code

Improve the work process and protect your investments with reliable G-code simulation

Why Eureka G-Code?

Why Eureka G-Code?

Verification of the programs allows you to avoid the risks of damaging expensive workpieces, tools breaking and collisions with machine parts such as the spindle, caused by programming errors.

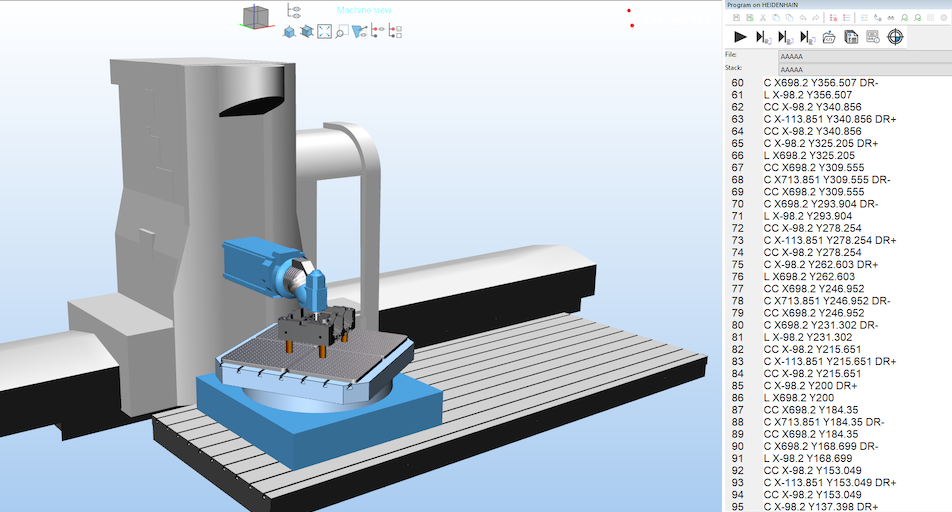

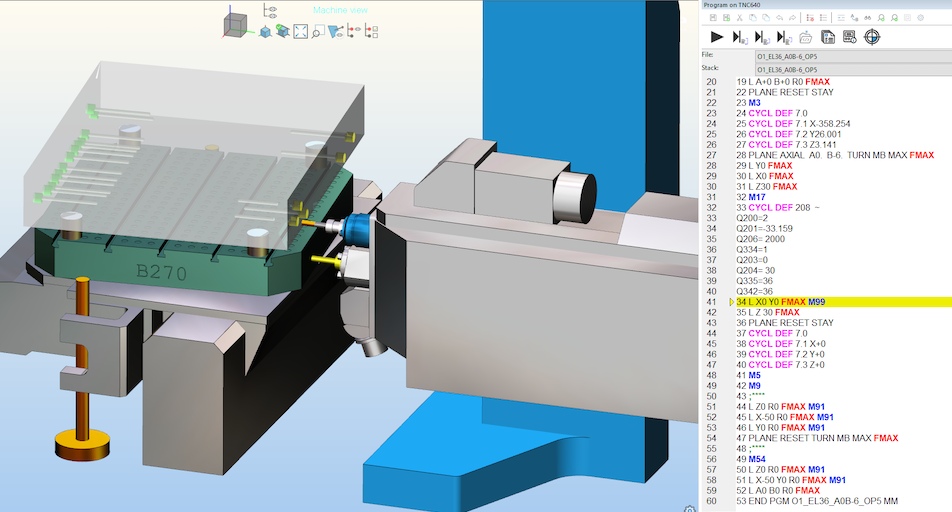

Independent simulation

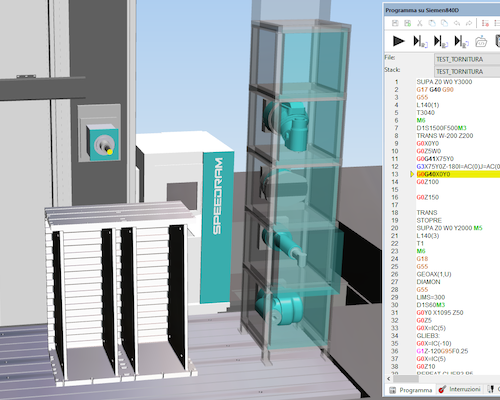

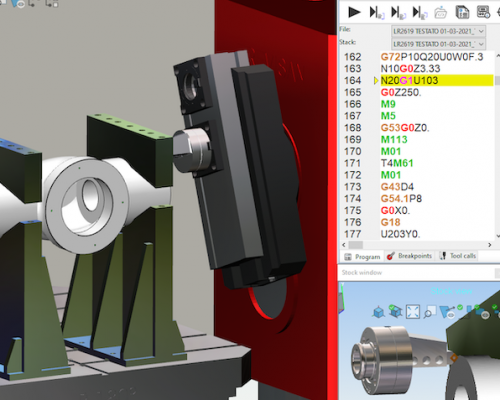

Eureka G-code simulates the actual G-code regardless of how it was created, either manually, or post processed from a CAM Program.

With Eureka G-code you can simulate, or emulate, all controller codes, including macros, parameters and constructor cycle variables such as:

Siemens G153-G500, SUPA, CYCLE 800, CYCLE976, CYCLE 81-87

Heidenhain PLANE SPATIAL, M91-M92

FANUC G68.2, G43.4, G81-G87, G53, G54.1P1

Reliable digital twin

Reliable digital twin for any type of kinematics and controller, including machines with more than 5 axes. You will have a complete collision check, including check between cutting edge and finished piece, and between tool holder and stock being machined, near-miss control between cutting edge and equipment, check for pre-holes for tapping and a verification of the limit switches.

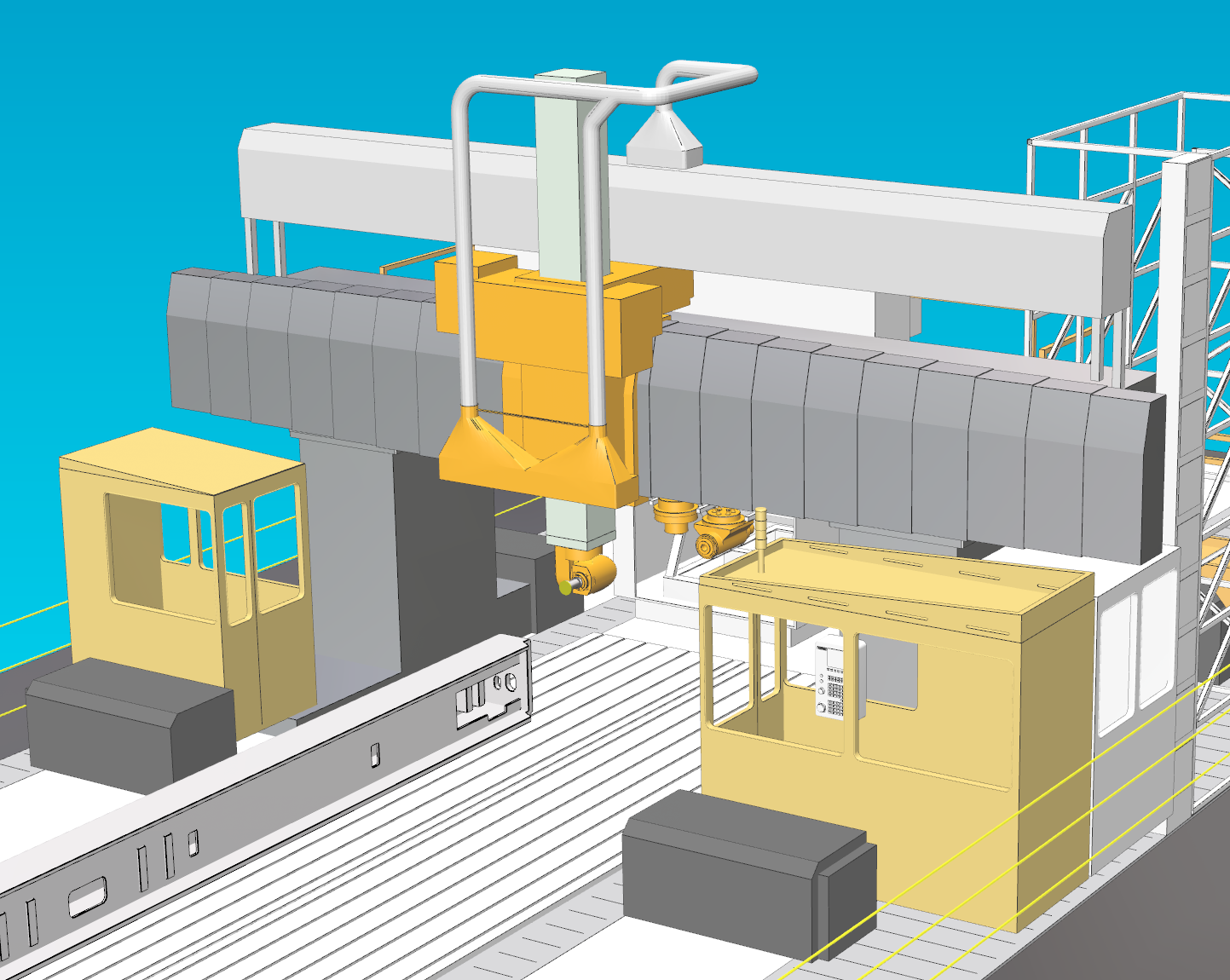

Tools simulation

In Eureka you can easy simulate machining centers, lathes, boring and milling machines for big pieces, including the management of head change, tables and dividers.

Supports all types of tools, including:

Special tools with Multi-cutting edges

Bareni in Tirata

Angular heads

D'Andrea heads

Tappers

Feelers

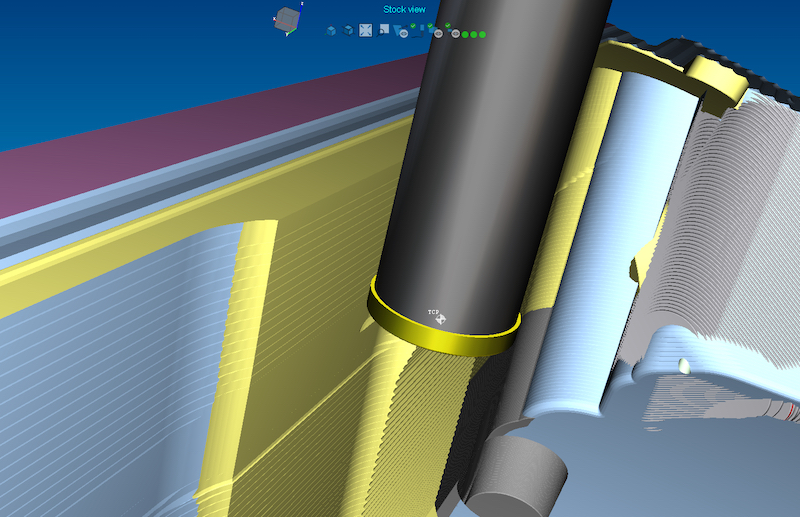

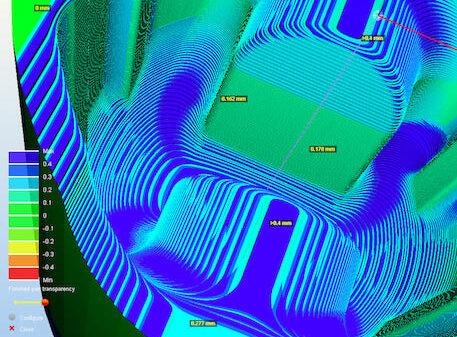

Super accurate comparison

Super accurate comparison

With Eureka you can have highly accurate comparison between machined piece and 3D of the finished one. This tool allows you to compare the CAD model of the finished product directly with the model of the machined blank obtained in simulation to identify and measure any differences, identifying gouges, excesses of material or other inconsistencies.

Cutting conditions check

For example, keep under control the volume removed in the unit of time for long tools that tend to vibrate. Ramp removal control for insert tools.

Some customers

Our customers about us

PAMA

“We chose Eureka for the ease of installation and use of the software, the ability to simulate machines with complex kinematics, the possibility of simulating parametric programs using advanced Siemens functions and last but not least, the excellent and timely technical support that Roboris provides" – Eng. Francesco Minutillo, Production Engineering Manager

Officina Meccanica Rosselli

“Mathematics, geometry and kinematics of Eureka simulations are perfectly faithful to what actually happens in the machine between the piece and the tool during the removal of material." – Alberto Roselli, owner

Omera

“In Omera we wanted Eureka a lot with the aim of simplifying and making “safe" milling and drilling operations very close and with limited maneuvering space that characterize our structures performed in heavy carpentry"

Super accurate comparison

Super accurate comparison