Evaluate quickly the results of your spraying toolpath

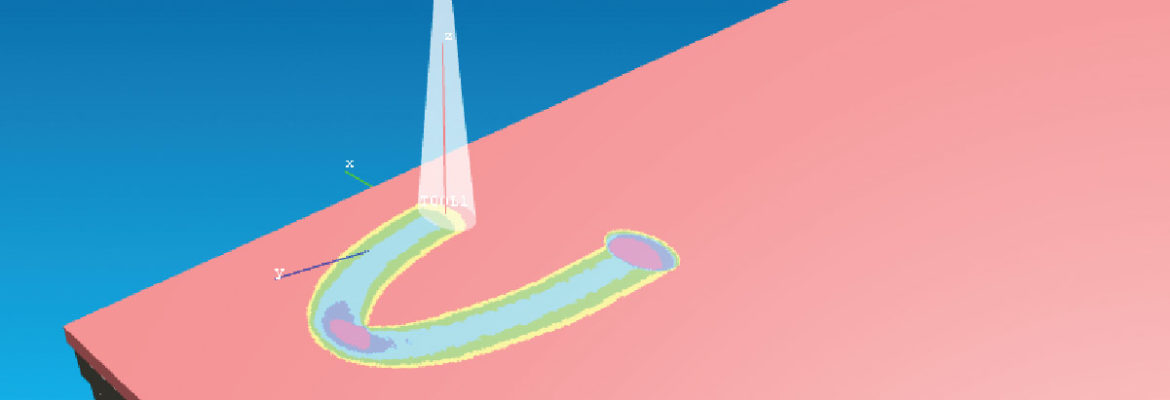

The spraying paths can be simulated and calibrated getting back an accurate estimate of the deposited material thickness.

Spraying simulation offers a preview of how the deposited material is distributed on the target surface and can detect any lack of material. For part-surfaces that require extra attention, material can be added or removed by directly modifying the toolpath in Eureka.

This prevents the need for multiple real-world tests, which saves both time and money.

The simulated spray pattern can be finely tuned using several parameters and multiple nozzles can be simulated.

Thickness of the deposited material can be calculated and displayed using a configurable color map.

The algorithms consider speed, distance, impact angle, and code or other technology parameters.

Clicking any point of interest displays the exact thickness at that point.