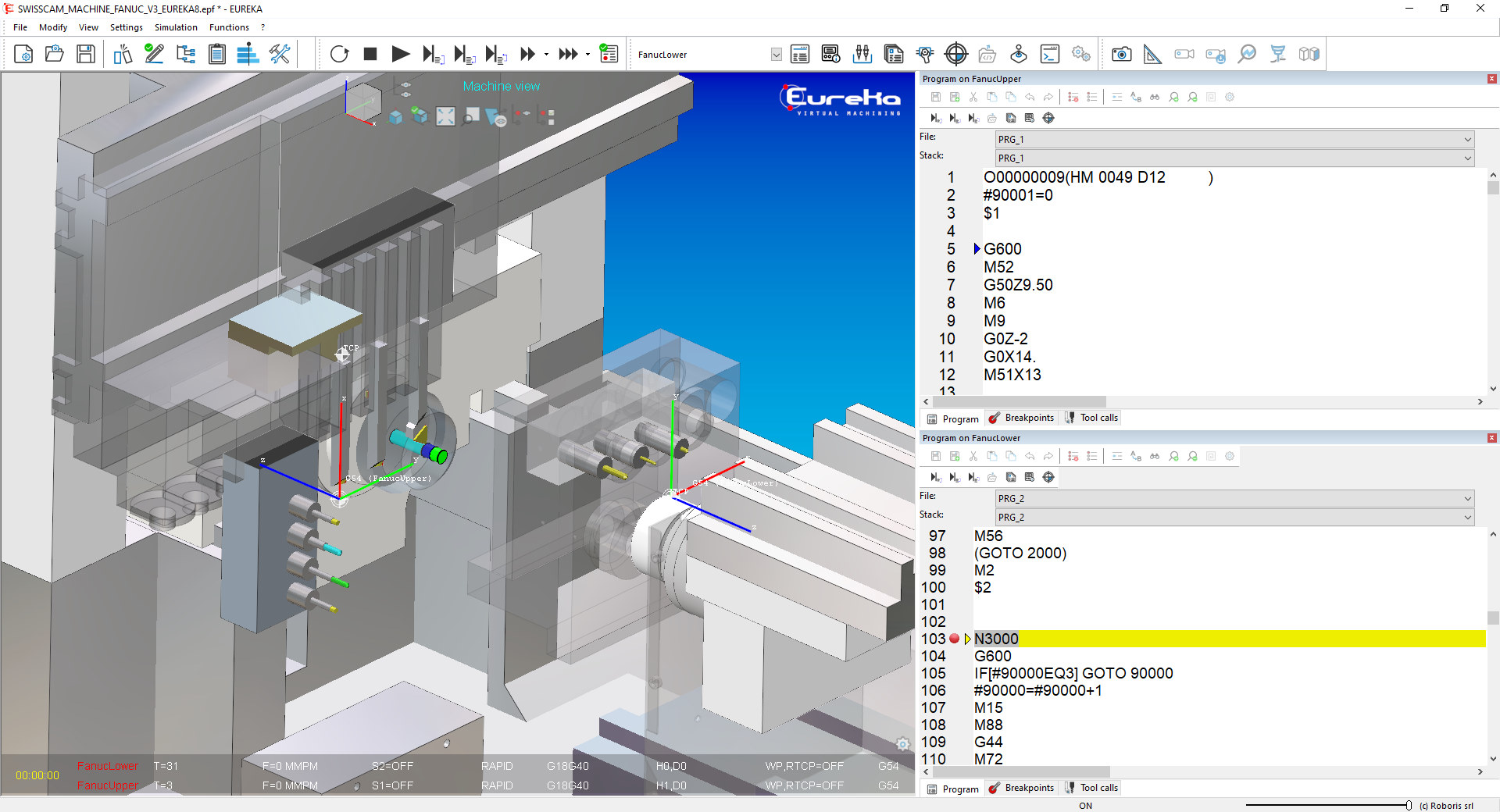

Eureka simulates the actual NC program (G-code) to be sent to Swiss machine, regardless of how it was created (manually or post processed from a CAM system).

Material removal is simulated in real-time, verifying errors like rapid motion contacts and collisions with the design model and fixtures.

A powerfull integrated editor enables real-time modifications of the G-code directly in Eureka, then simulate again without restarting the process.

Tools defined either by parametric models, or starting from a 2D profile or 3D model.

Real-time collision detection between all machine parts, stock ad fixtures.

Real-time visualization of coordinate systems and tool reference points.

Verification of over-travel limits, JOG and MDI functionalities.

Automatic workpiece transfer to pick-off or sub spindles.

Accurate management of bar feeders and sliding headstock machines.