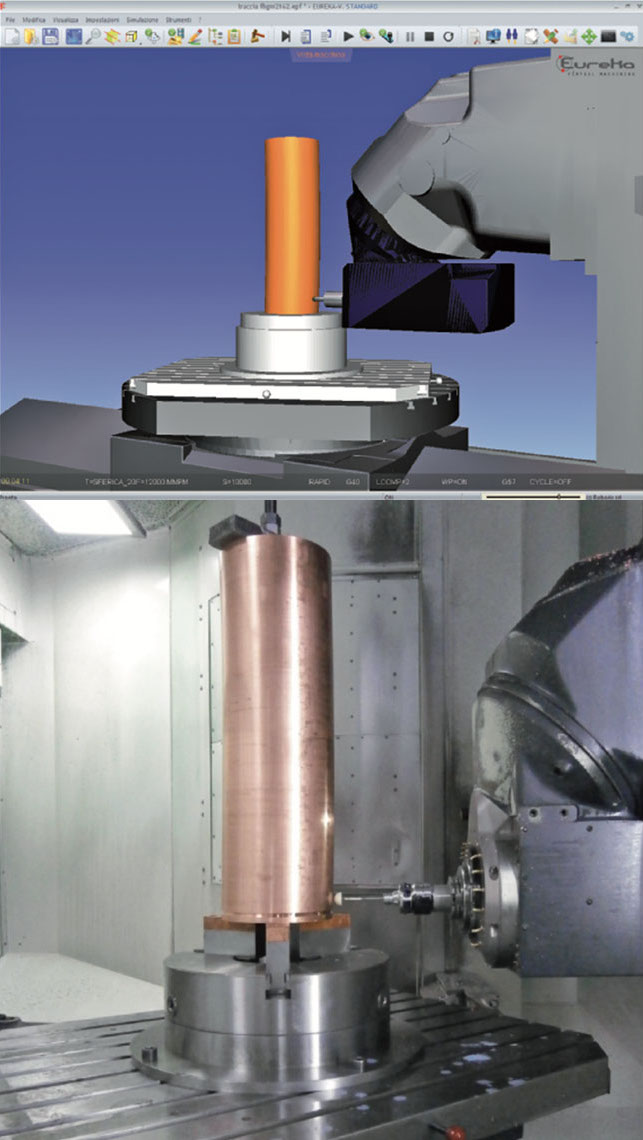

EM Moulds Srl, an industry leading and global manufacturer of copper ingot molds, use Eureka software for simulation and verification of 3 thru 5 axis CNC G-code programs.

Giovanni Mori – production manager of Em Molds, is very satisfied with the results achieved using Eureka: “Eureka simulation allows us to understand very clearly if our G-code programs are correct, or if it’s necessary to make changes before starting the machine. Mathematics, geometry and kinematics displayed on the screen are highly accurate to what actually happens on the machine between part and tools. We have significantly reduced errors, collisions and machine downtime”.

“Furthermore, Eureka allowed us to get to know the machines better, improving the skills and knowledge of the operators upstream. The decrease in errors is significant, with a reduction in waste of 50-60% and this means a time saving of at least 20-30%.”

“Furthermore, Eureka allowed us to get to know the machines better, improving the skills and knowledge of the operators upstream. The decrease in errors is significant, with a reduction in waste of 50-60% and this means a time saving of at least 20-30%.”

“Before using Eureka, we wasted significant time trying out programs in order to detect problems, which then required reprogramming and further tryouts on the machines. Today, thanks to Eureka and their CNC Machine’s “Digital Twin”, EM Molds gets to production much faster and more safely, particularly with their 5-axis machines, because G-code programs are now “fully verified and validated” in Eureka prior to production.”

More than 100 years experience!

| EM MOULDS is an Italian company specialized in the field of copper moulds for continuous casting of steel. It can look back to more than 100 years of experience in the field of copper and copper alloys. EM MOULDS has its registered office in Florence.EM ingot mould production plant and its sales offices are located at Fornaci di Barga, near Lucca. EM commercial network of agencies covers the entire world market. |