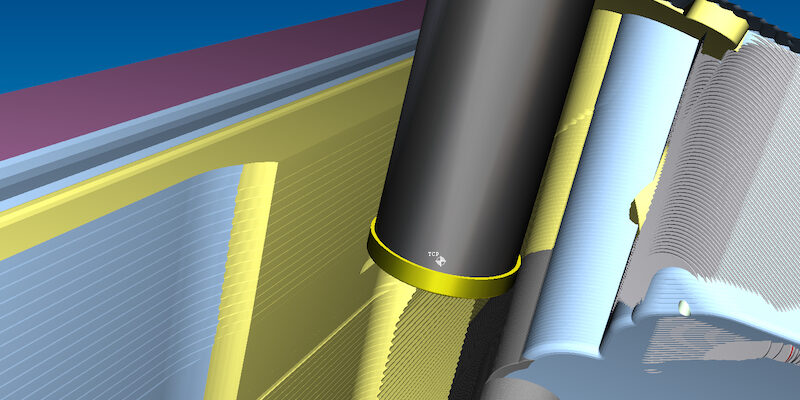

Verification of cutting conditions For example, keep under control the volume removed in the unit of time for long tools that tend to vibrate. Ramp removal control for insert tools.

Eureka G-Code Archives - Roboris

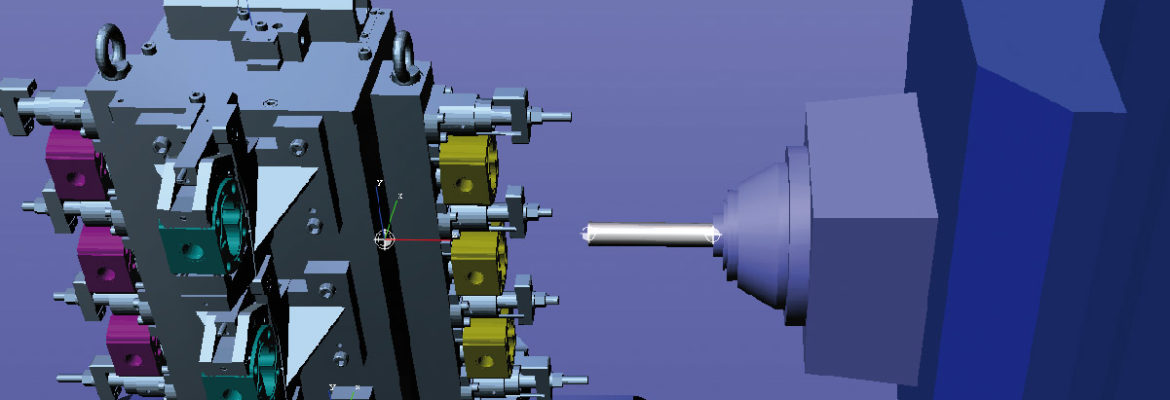

Production machines

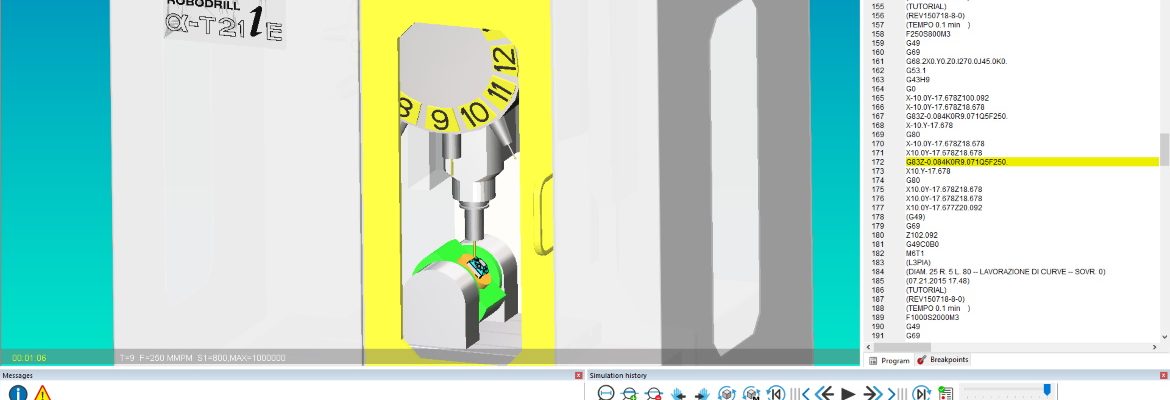

Simulation of multiple workpieces, multiple pallets and multiple origins machining, including tool changes and piece probing cycles. Machining simulation with multiple workpieces, pallets and program zeros. Accurate emulation of the Fanuc and Siemens G-codes including logic and mathematical functions. Tilted work planes simulation (G68.2, PLANE SPATIAL, CYCLE800). Simulation of tombstones, tool changes and probing cycles.

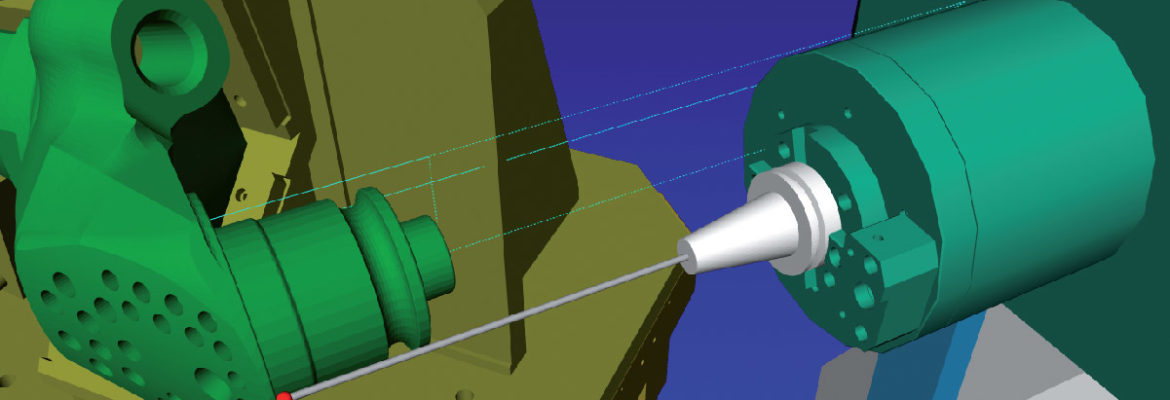

Multi-Channel Mill-Turn Machines

Simulation of multi-channel mill-turn machines running independent, synchronized or continuous 5 axes routines. Unlimited axes. Continuous 5-axis and simultaneous mill-turn machinings on different spindles and workpieces. Multiple repetitive cycles emulation (G71, G72 for Fanuc and CYCLE93-CYCLE95 for Siemens 840D). Mill-turn machining toolpaths using Z, X and C axes or Z, X and Y axes

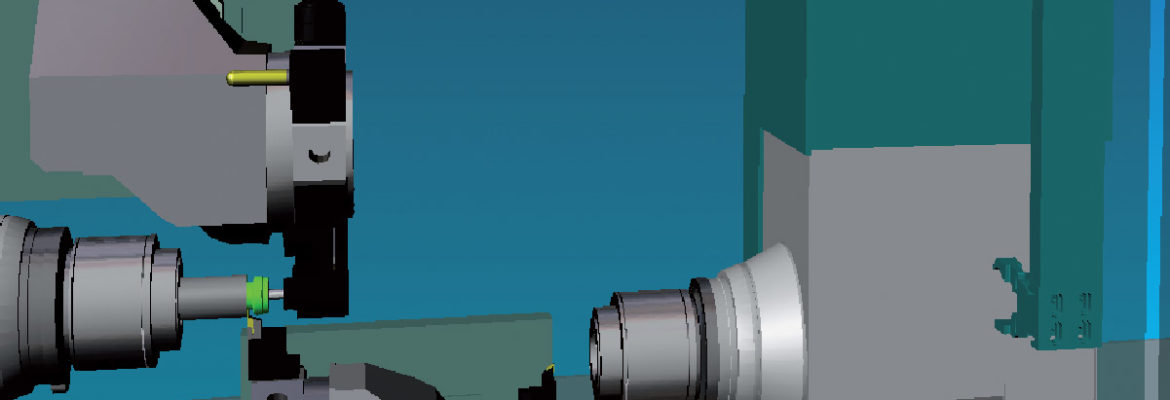

Probing cycles

By verifying the probing cycles in Eureka G-Code, it is possible to detect errors that could break the probe, or crash your machine. Eureka simulates all aspects of probe cycles. If an error is detected it is possible to modify the program immediately using the integrated editor and test it again

Training and Education

Eureka is a useful tool for training new personnel and teaching NC programming to students. NC programs for any kind of machine and control can be designed and verified with Eureka, even when the real machine is not available.

Eureka Mobile

Review your simulation on your mobile devices. Thanks to EurekaMobile any simulation made by Eureka Virtual Machining can be reviewed and analyzed anywhere on all mobile devices. Machine tool operators can now review the NC program simulation on their own mobile devices enabling an optimal machine setup. Potential critical issues flagged by the technical office

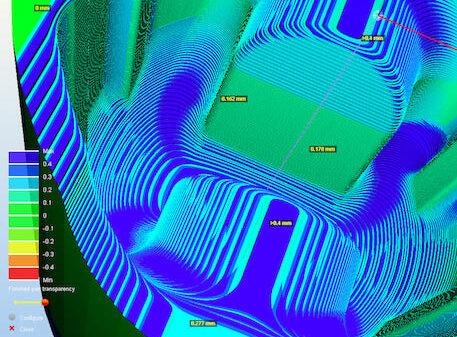

Super accurate comparison

Compare the machined stock with a super accurate comparison With Eureka you can have highly accurate comparison between machined piece and 3D of the finished one. This tool allows you to compare the CAD model of the finished product directly with the model of the machined blank obtained in simulation to identify and measure any