Eureka G-code

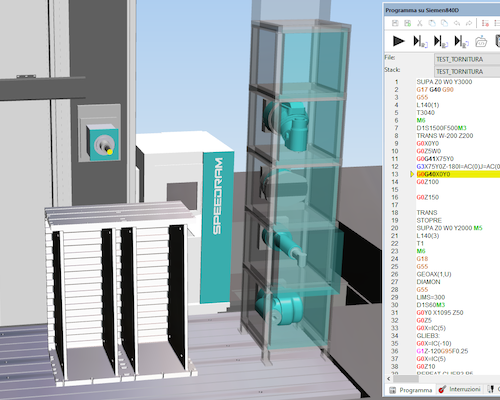

Simulation for CNC Machine Tools with Eureka G-Code

Improve the work process and protect your investments with reliable G-code simulation

为什么选择 Eureka G-Code?

为什么选择 Eureka G-Code?

程序验证可让您避免因编程错误而损坏昂贵工件、刀具断裂和与主轴等机器零件发生碰撞的风险。

独立的仿真

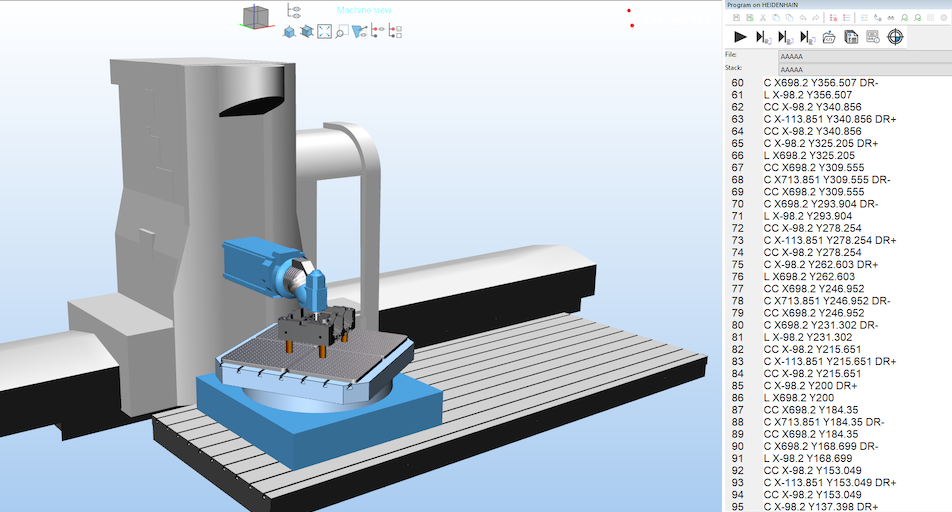

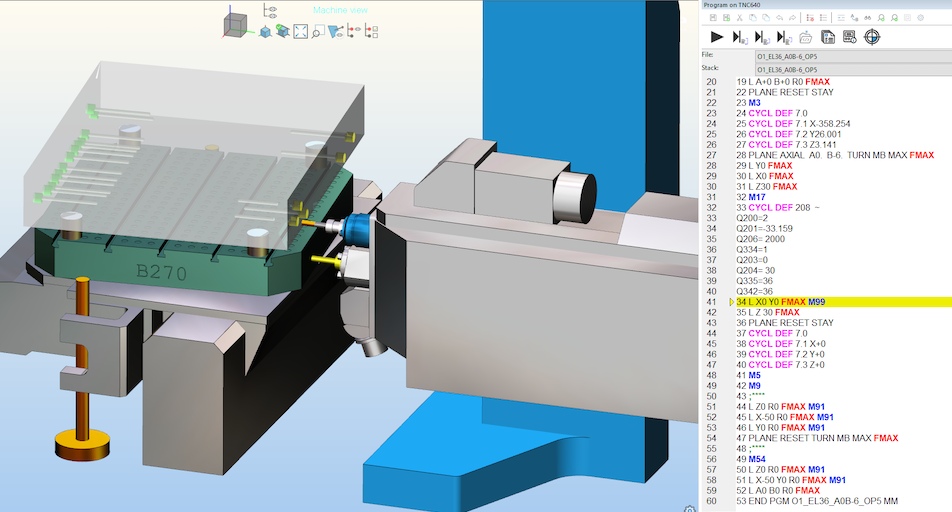

Eureka 模拟发送到机器的实际 G 代码,无论是手动创建还是任何 CAM 系统后处理的生成的。

使用Eureka G-Code,您可以模拟或仿真所有控制器代码,包括宏,参数和构造函数周期变量,如:

- 西门子 G153-G500, SUPA, CYCLE 800, CYCLE976, CYCLE 81-87

- 海德汉 PLANE SPATIAL, M91-M92

- 发那科 G68.2, G43.4, G81-G87, G53, G54.1P1

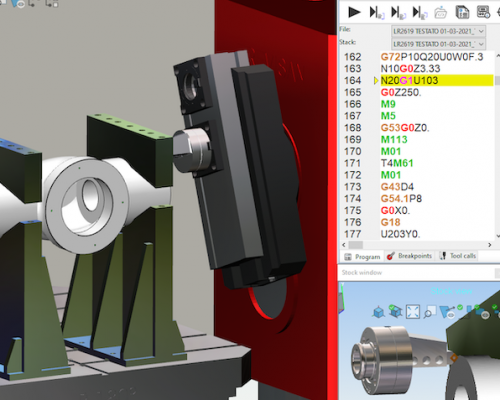

Reliable digital twin

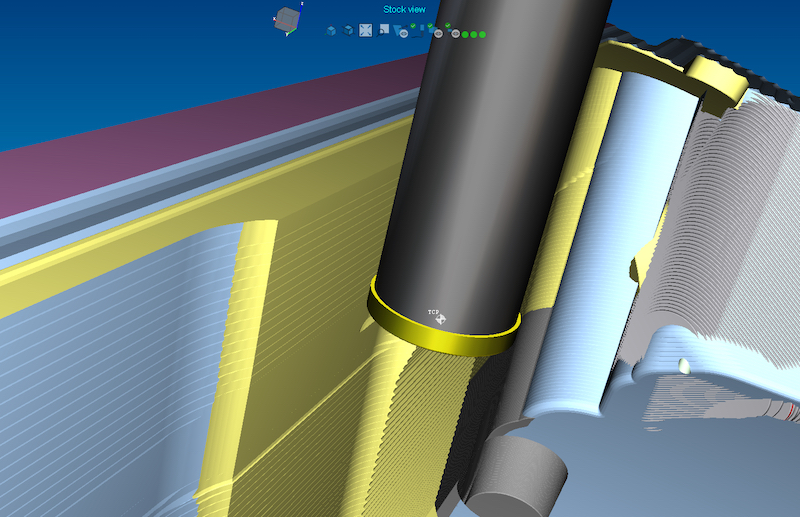

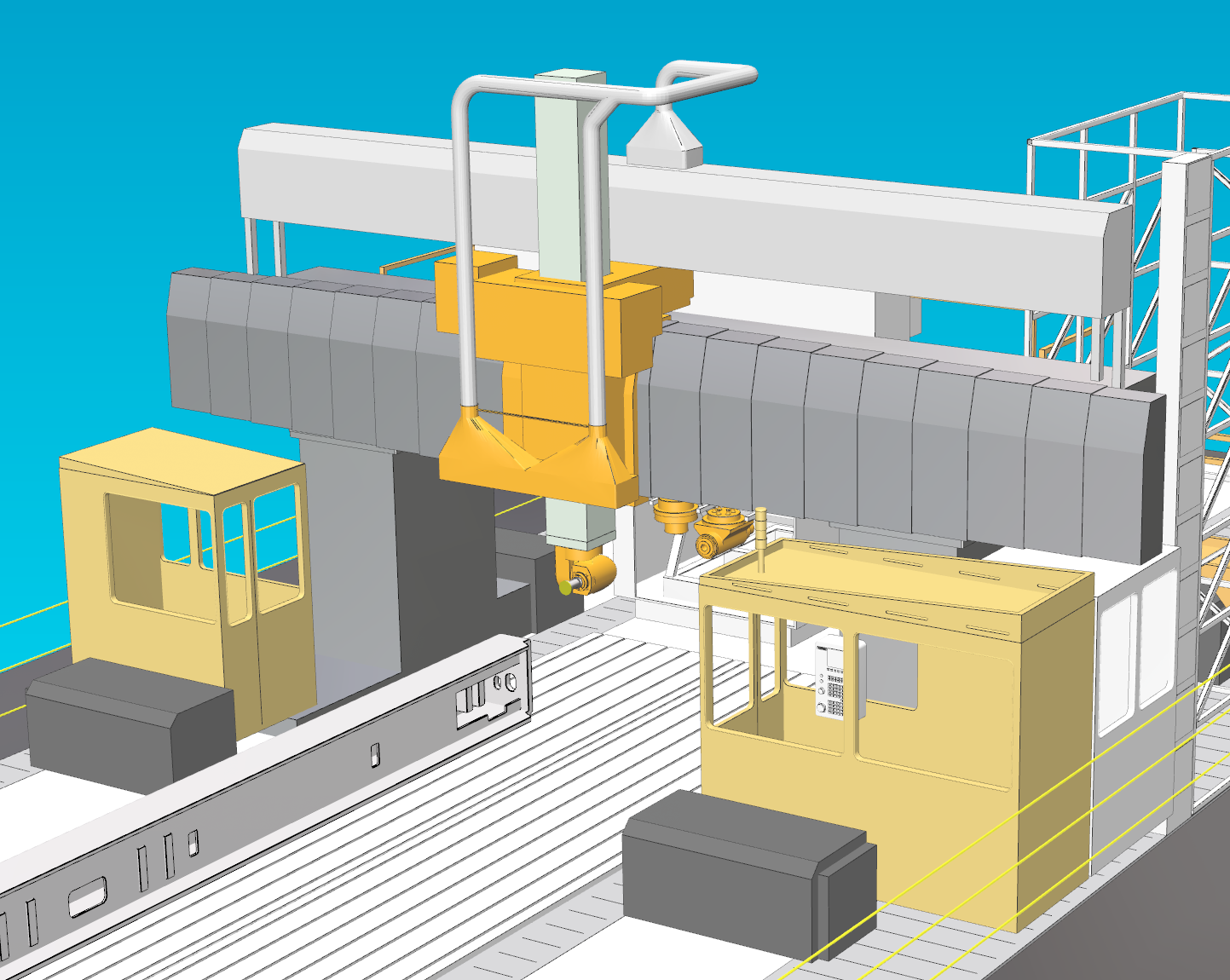

Reliable digital twin for any type of kinematics and controller, including machines with more than 5 axes. You will have a complete collision check, including check between cutting edge and finished piece, and between tool holder and stock being machined, near-miss control between cutting edge and equipment, check for pre-holes for tapping and a verification of the limit switches.

刀具模拟

在 Eureka 中,您可以轻松地模拟加工中心、车床、镗床和铣床等大型工件,包括更换头、工作台和分隔器的管理。

支持所有型号的刀具,包括:

Special tools with Multi-cutting edges

Bareni in Tirata

角度头

D'Andrea heads

攻丝机

Feelers

Super accurate comparison

With Eureka you can have highly accurate comparison between machined piece and 3D of the finished one. This tool allows you to compare the CAD model of the finished product directly with the model of the machined blank obtained in simulation to identify and measure any differences, identifying gouges, excesses of material or other inconsistencies.

Cutting conditions check

For example, keep under control the volume removed in the unit of time for long tools that tend to vibrate. Ramp removal control for insert tools.

一些客户

评价我们

PAMA

“我们选择 Eureka 是因为该软件易于安装和使用,能够模拟具有复杂运动学的机器,能够使用先进的西门子控制器功能模拟参数程序,最后同样重要的是,Roboris 提供的出色和及时的技术支持” – Eng.Francesco Minutillo,生产工程经理

Officina Meccanica Rosselli

“Eureka 模拟的数学、几何和运动学完全忠于机器在去除材料期间工件和刀具之间实际发生的情况。”

Omera

“在 Omera,我们非常需要 Eureka,其目的是简化和在机动空间有限的条件下使“安全”铣削与钻孔操作非常接近,这是我们在重型木工操作中的结构特征”