Online Calculator

Estimate how much you can save

with Eureka G-Code

Insert your data and find out how much you could save

using Eureka G-Code

Accurate, reliable and interfaceable

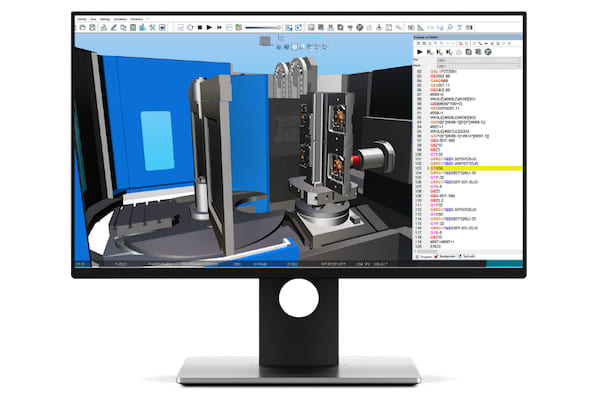

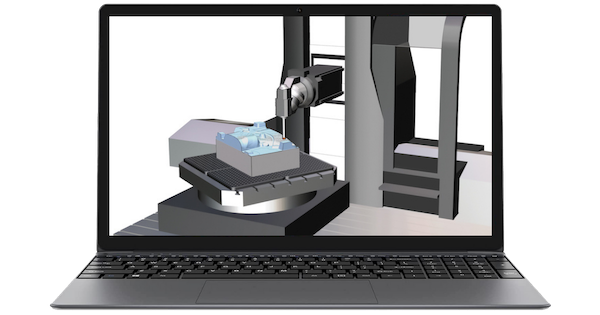

Eureka Virtual Machining is a suite of products for verification, simulation and optimization of NC machine tools and robots, developed by Roboris. Eureka simulates the actual G-code regardless of how it was created, either manually, or post processed from a CAM Program.

Thanks to the interfaces available for the major CAD/CAM systems and the main tools of tools it is possible to transfer raw, finished equipment, programs and, above all, the tools in a few clicks.

Enter your contact info to schedule a live Eureka demonstration

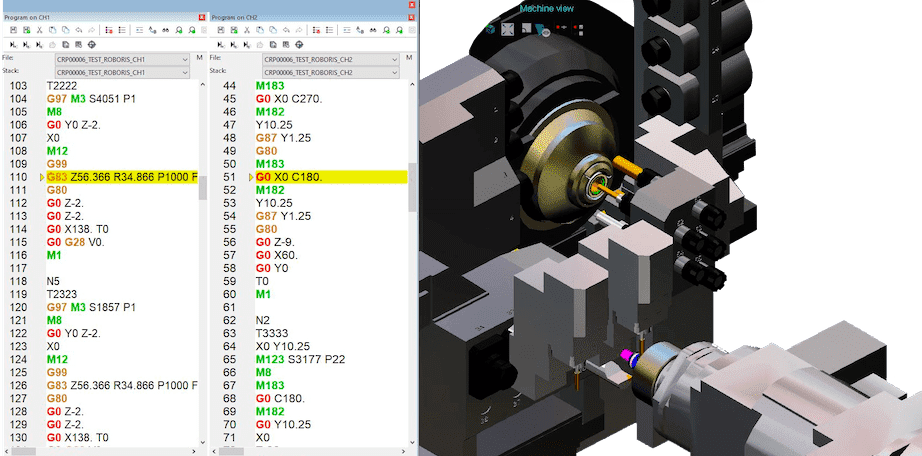

Eureka G-Code simulates the actual G-code regardless of how it was created, either manually, or post processed from a CAM Program. Eureka performs simulation based on a highly accurate and reliable “digital twin” of the machine tool and CNC controller.

The majority of CAM programs simulations do not consider macros, subroutines and cycles. The CAM simulation doesn’t consider the “machine zero", axis strokes, or the management of multi-heads and do not manage multi-heads, machines with more than 5-axes and also probing routines.

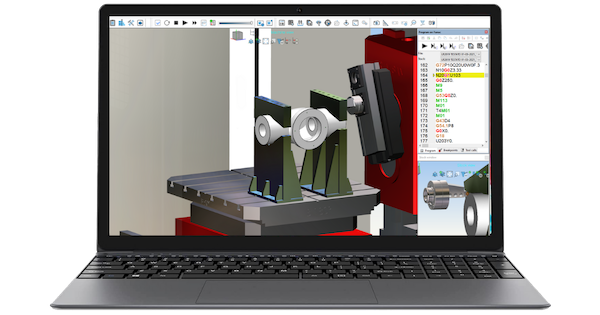

Find the best set-up on Pc

With Eureka G-Code you can reduce machine setup time by up to 80%. In Eureka you can simulate and verify all ISO programs without taking the real machine out of production.

Avoid the risk of collision

Programming errors are often the cause of collisions and damage. The result is wasted programming hours, damage of expensive workpieces, tools breaking and collisions with machine parts such as the spindle.

Save your money

Star saving your money using a perfect digital twin of your real machine

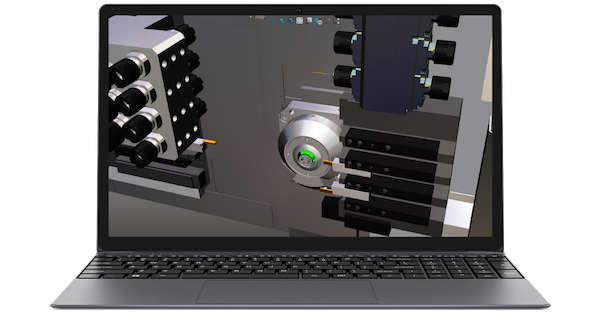

Reduce machining time and reduce your tool costs by optimizing cutting conditions

Thanks to a sophisticated digital-twin of the material removal process and to an innovative method patented by Roboris, Eureka automatically optimizes the cutting conditions of the tools by modulating the feed rate to reduce the cycle time, increase the life time of the tool, decrease the stress on the machine axes and improve the consumption of electrical energy.

Advantages

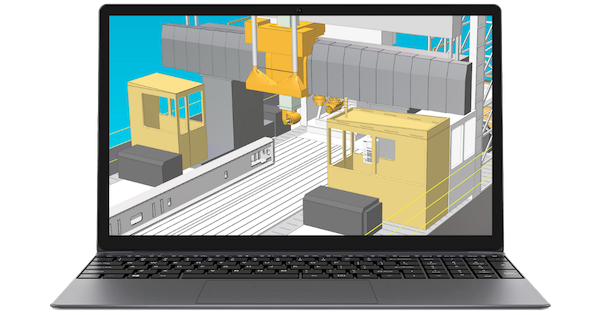

Eureka Virtual Machining allows you to have a digital replica of the machine on your PC and allows you to:

Eliminate machining test

Avoid risk of damages

Reduce set-up time

Improve the quality of products

Reduce processing waste

Reduce tools costs

Some of the applications of Eureka G-Code

Partner & Customers

Our customers range from small mechanical workshops to multinational companies in automotive, aerospace and many other sectors

The presence of Roboris in 5 continents, the ability to customize the product at 360 ° and a high quality technical support allows us to establish a true long-term partnership with our customers that guarantees to get the best from the Eureka Virtual Machining suite.

Copyright © 2020 Roboris Srl – Via Sterpulino 1G – 56121 Ospedaletto (Pisa) – Italy – P.I. 01566380505 – All rights reserved | REA: PI – 137214 | Capitale sociale: 12.000€ I.V.

Copyright © 2020 Roboris Srl – Via Sterpulino 1G – 56121 Ospedaletto (Pisa) – Italy – P.I. 01566380505 – All rights reserved | REA: PI – 137214 | Capitale sociale: 12.000€ I.V.